Our Bal Conn® electrical connector is the component of choice for designers who need to make reliable, consistent connections in active medical implantables for cardiac rhythm management and neuromodulation. For more than 20 years, it has been improving device performance, supporting emerging therapies, and making smaller, more functional devices possible. Its uncompromising conductivity and compact design make it ideal for use in devices with high connection counts.

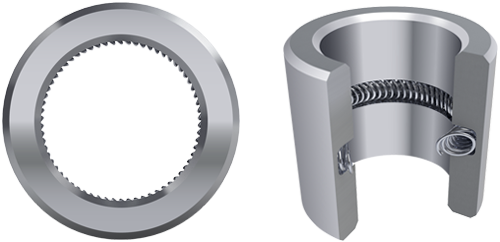

Bal Conn Electrical Connector Construction

Consisting of a housing made from medical-grade alloys and a Bal Spring® canted coil spring, the Bal Conn electrical connector is precision-built to help device designers connect with confidence. Its spring coils ensure ultra-reliable multi-point electrical contact with superior resistance to fatigue.

Bal Conn electrical connector housings are typically cylindrical, but their geometry can be customized to incorporate features that aid in connector retention and simplify assembly processes.

Bal Conn Electrical Connector Sizes Down to 0.6 mm

The Bal Conn electrical connector plays a big role in the consistent, reliable operation of active medical implantables. But it keeps a very low profile, managing more power in less space than any other leading contact technology. With our advanced manufacturing processes, we can produce these connectors with inside diameters ranging from 0.024 in. (.6 mm) to 0.39 in. (10 mm)+.

Bal Conn Electrical Connector Function

The Bal Conn® enables transmission of power from the battery and electronics to the lead in implantable medical devices. Typically, multiple Bal Conn electrical connectors are arranged in a serial configuration as part of the interconnect system in a device header, or in an interconnect for a lead segment that helps reduce patient risk. The connector’s canted coil spring element aligns with an electrode on the device lead, creating a reliable connection with very low contact resistance (<100 mΩ).

Bal Conn Electrical Connector Configurations

We offer Bal Conn electrical connectors in configurations that meet requirements for current and emerging neuromodulation technologies, as well as industry standards for implantable cardiac devices. These connector designs can be integrated into your device as a turnkey solution, or they can serve a baseline for accelerated customization.

|

|

| Bal Conn Neuro |

|

|

| Bal Conn IS-1 | |

|

|

| Bal Conn Radial IS-4/DF-4/VAD | |

|

|

| Bal Conn Axial IS-4/DF-4 |

Bal Conn Electrical Connector Performance

Electrical connector performance can be influenced by size, housing and spring material selection, spring coil density, and many other factors. With our design experience and consultative engineering approach, we can help you make the best choices for your device. Here’s a look at some general Bal Conn® performance characteristics.

Nominal Static Dry Contact Resistance (mΩ)*

Running Force Range (N)

Maximum Breakout Force (N)

*Tolerances for this value can range from +/- 15 mΩ to +/- 200 mΩ, depending on a variety of physical and material factors. Contact us, and we’ll help you achieve the optimal electrical performance.

Bal Conn Electrical Connector Materials

Our Bal Conn electrical connector is available in a range of implantable-grade, biocompatible housing and spring materials.

Bal Conn Electrical Connector Spring Force

At the heart of the ultra-reliable Bal Conn electrical connector is our proven Bal Spring® canted coil spring technology. Our spring exerts a near-constant force across the working deflection range, and its forces remain consistent. The spring resists compression set, and its individual coils compensate for misalignment, tolerance variations, and mating surface irregularities. Its multiple coils also provide contact redundancy. The spring’s mechanical and electrical properties enable Bal Conn to outperform other connector technologies.

Bal Conn Electrical Connector Applications

Bal Conn Electrical Connector Customization

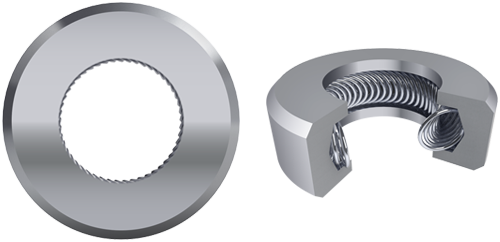

If your device design requires connectors with special features or geometries, we’ve got you covered. Bal Conn electrical connectors can be customized to fit your unique product and process needs, simplifying installation and integrating seamlessly with your manufacturing methods. Here are some examples:

Bal Conn with flat side for improved device header integration.

Bal Conn with OD groove for welding process integration.